3-Day Industrial Automation Training at TOC H Institute of Science and Technology

CodX Systems

Published on 7/7/2025

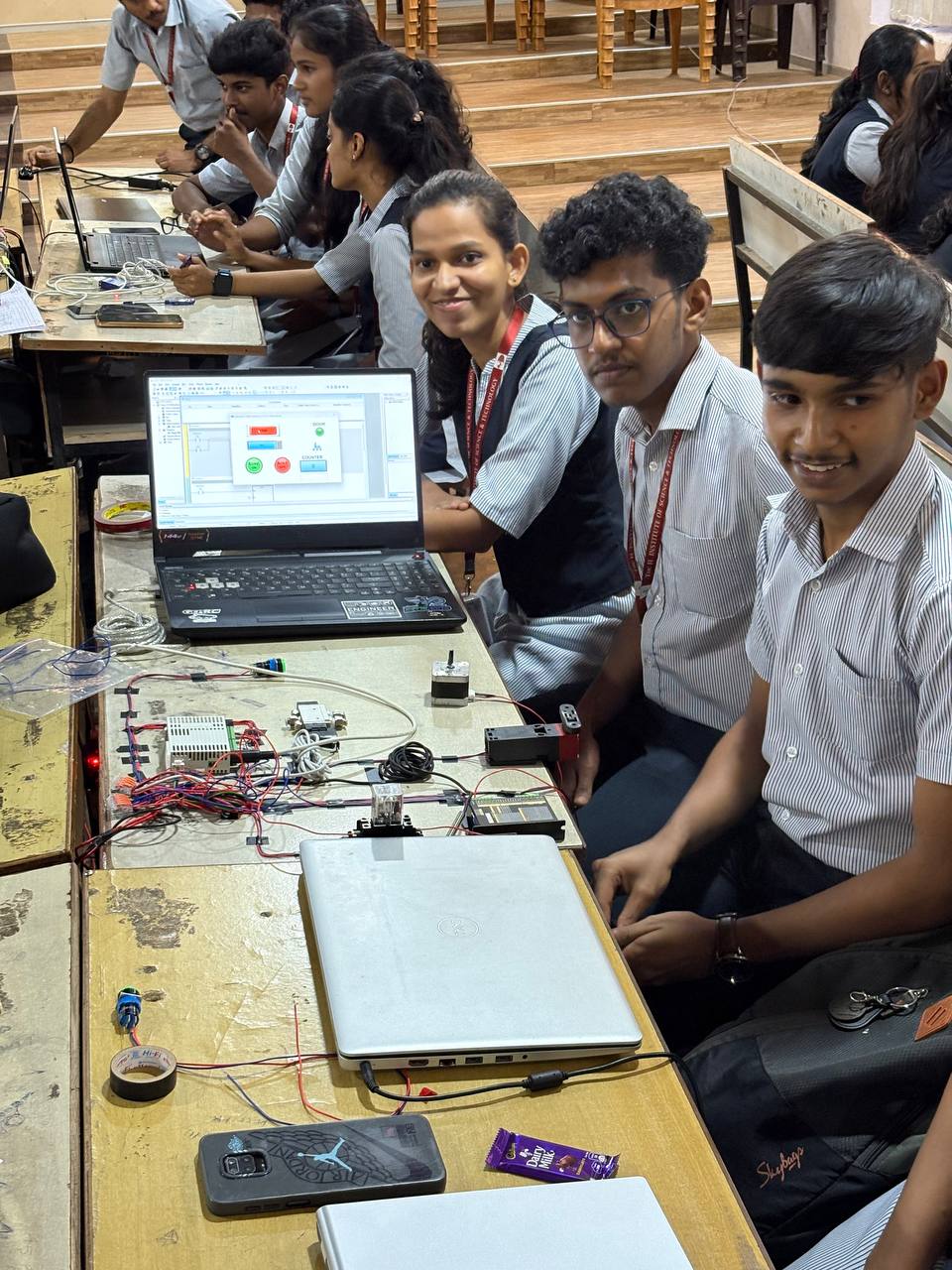

At CodX Systems, we believe true learning happens through real industrial experience, not just classroom kits. That's why our 3-Day Hands-On Industrial Automation Training at TOC H Institute of Science and Technology, Arakunnam gave students access to actual industry-grade PLCs, sensors, actuators, and control systems—the same technologies used in manufacturing plants and automation industries today.

The workshop was conducted for first-year students from the Robotics & Automation and Electronics & Communication departments.

Making Students Industry Ready

Designed to bridge the gap between academics and industry, the training covered PLC programming, pneumatics, sensor-actuator integration, HMI design, and industrial safety systems. Students learned how automated systems operate end-to-end—from wiring and programming to testing and execution.

Day-Wise Highlights

Day 1 – Introduction to Industrial Automation and PLC Basics

Students were introduced to industrial automation concepts, smart manufacturing, and PLC fundamentals. They performed real PLC wiring, ladder logic programming, and I/O testing, gaining hands-on familiarity with industrial components.

Day 2 – Pneumatics, Safety Systems, and HMI Integration

Participants explored pneumatic actuators, solenoid valves, and industrial safety devices such as light curtains and door switches. They also designed HMI screens and integrated them with PLC logic, learning how automation control is visualized and operated in real facilities.

Day 3 – Group-Based Industrial Automation Projects

On the final day, students were divided into groups and challenged to design and execute their own mini industrial automation projects. These projects combined PLCs, sensors, actuators, and HMIs, mirroring real-world industrial problems. Each group presented their system, demonstrating logic design, electrical interfacing, and automation control.

Why Industry-Grade Training Matters

Unlike theoretical workshops with simulation software or mini kits, our training used full-scale industrial equipment. Students worked with real PLCs from leading brands, industrial-grade sensors and actuators, professional HMI panels, and authentic safety systems—giving them the confidence and competence to step into industrial roles immediately after graduation.

At CodX Systems, we're committed to shaping the next generation of automation engineers—not just through theory, but through real-world exposure and hands-on practice.

Tags

Related Articles

Continue exploring automation and robotics insights

Stay Updated with Industry Insights

Get the latest articles on automation, robotics, and industrial innovation delivered to your inbox.